Bioluminescent Bacteria

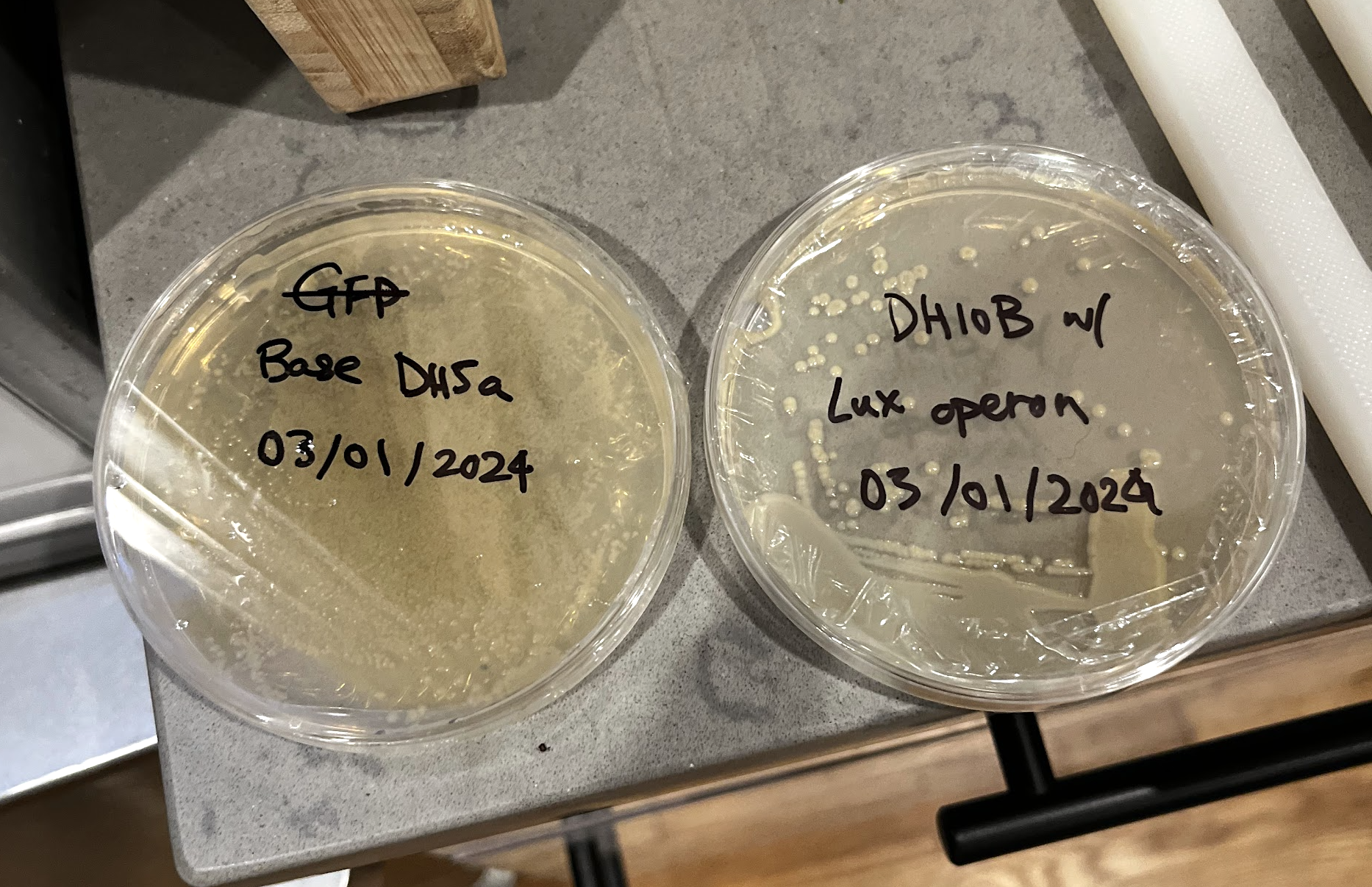

This project explored the creation of bioluminescent bacteria through genetic transformation. The goal was to introduce the Lux operon into a base strain of E. coli, resulting in bacteria that could produce visible light.

Materials and Preparation

The project began with the acquisition of key components:

- A base strain of E. coli

- Bacteria containing the Lux operon in the pJE202 plasmid

- Mini prep kit

- Agar & plates

- Centrifuge

- Incubator (repurposed 3D printer)

- LB (Lysogeny Broth) medium

- Kanamycin (sourced from an aquarium store)

- Calcium chloride

- Autoclave (Instapot)

Prior to any experimental work, all equipment and materials were sterilized. This was achieved by maintaining a temperature of 121°C for at least 15 minutes. An accessible method for sterilization involved placing materials and tools into an Instant Pot with a small amount of water, then running it at high pressure for 20 minutes. This step was crucial to prevent contamination and ensure the integrity of the experiments.

The Lux operon, while originally discovered in marine bacteria like Vibrio fischeri, was in this case already incorporated into a laboratory strain of bacteria. This strain also carried kanamycin resistance, which would later serve as a selection marker.

Kanamycin, typically an expensive laboratory-grade antibiotic, was sourced from an aquarium store where it's used to treat fish diseases. This sourcing significantly reduced costs without compromising the experiment.

Plasmid Extraction

To transfer the Lux operon to the base E. coli strain, the plasmid needed to be extracted. A mini prep kit was used for this purpose, following these steps:

- Cultured the DH10B-based E. coli in LB

- Centrifuged to collect cells

- Resuspended cells in a buffer

- Lysed cells to release plasmid DNA

- Neutralized and removed cell debris

- Bound plasmid DNA to a silica membrane

- Washed to remove contaminants

- Eluted purified plasmid DNA

Bacterial Transformation

The calcium chloride method was employed to transform the base E. coli with the extracted plasmid:

- Grew base E. coli overnight in 3 ml of LB at 37°C

- Added 0.5 ml of overnight culture to 50 ml prewarmed LB

- Monitored growth until OD600 reached 0.35-0.4

- Chilled culture on ice

- Centrifuged at 6,000 rpm for 8 minutes at 4°C to collect cells

- Resuspended cells in 20 ml ice-cold 50 mM CaCl2

- Incubated on ice for 20 minutes

- Centrifuged again and resuspended in 2.5 ml ice-cold 50 mM CaCl2

- Added isolated pJE202 plasmid to 100 μl competent cells

- Incubated on ice for 30 minutes

- Heat shocked at 42°C for 1 minute

- Immediately transferred to ice

- Added 1 ml LB and incubated at 37°C for 30 minutes

- Plated on agar containing kanamycin

Incubation in a 3D Printer

A Bambu Lab 3D printer was repurposed as an incubator for this project. The temperature was carefully maintained below 30°C to prevent denaturing of the light-producing proteins. This approach demonstrated how readily available equipment could be adapted for specialized scientific purposes.

Colony Selection and Culture

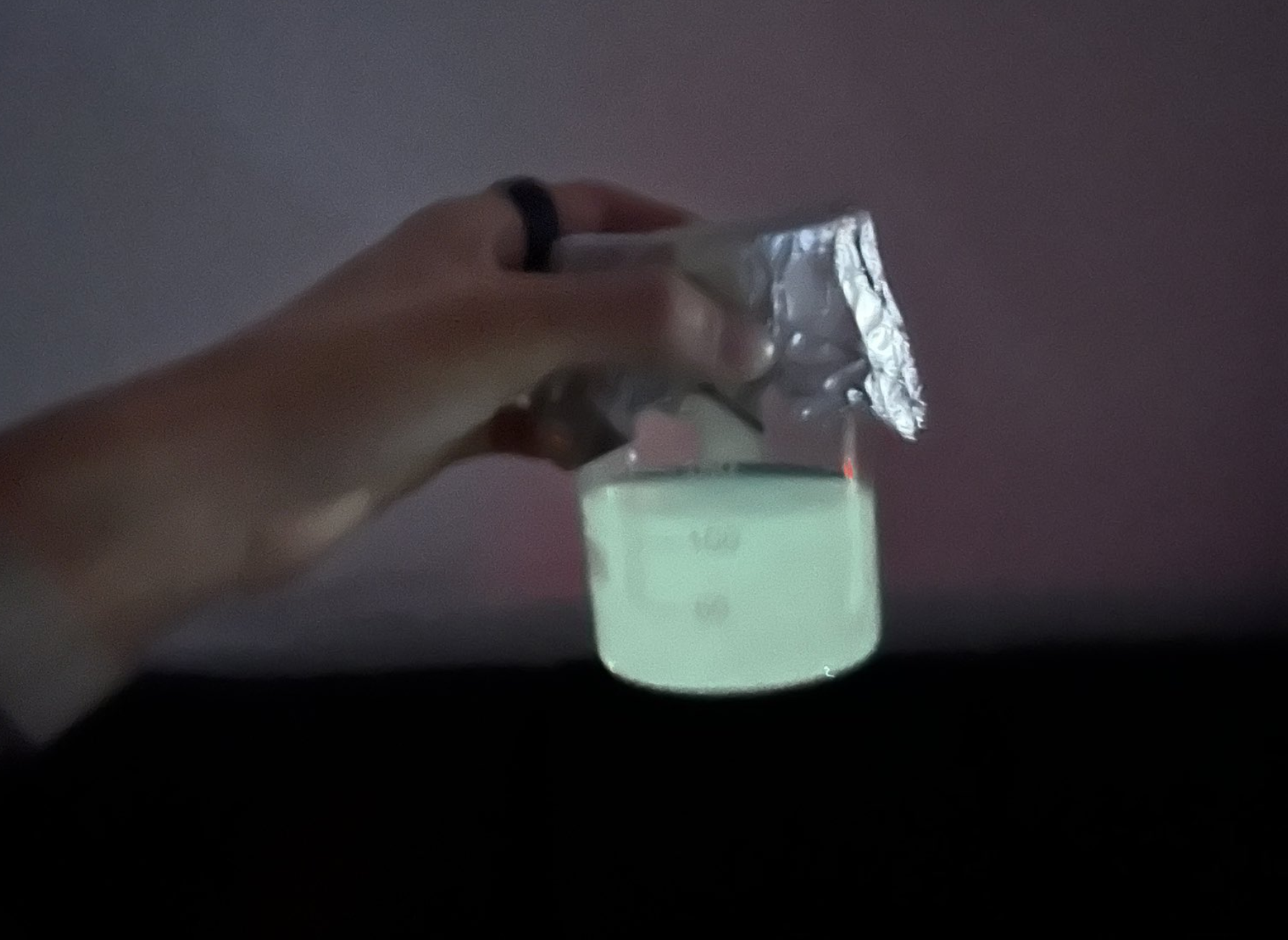

After incubation, a single glowing colony was selected from the agar plate. This colony was then grown in liquid broth to obtain a pure culture of bioluminescent bacteria, maximizing light output for potential applications.

Future Directions

The transformation successfully produced bioluminescent E. coli colonies.

Future plans for this project include:

- Incorporating the bioluminescent bacteria into a necklace, creating a stable ecosystem with other bacterial species.

- Exploring genetic modifications to alter the bacteria's light emission, potentially creating strains that are naturally blue during the day and glow at night.