Building a Pulse Jet Engine

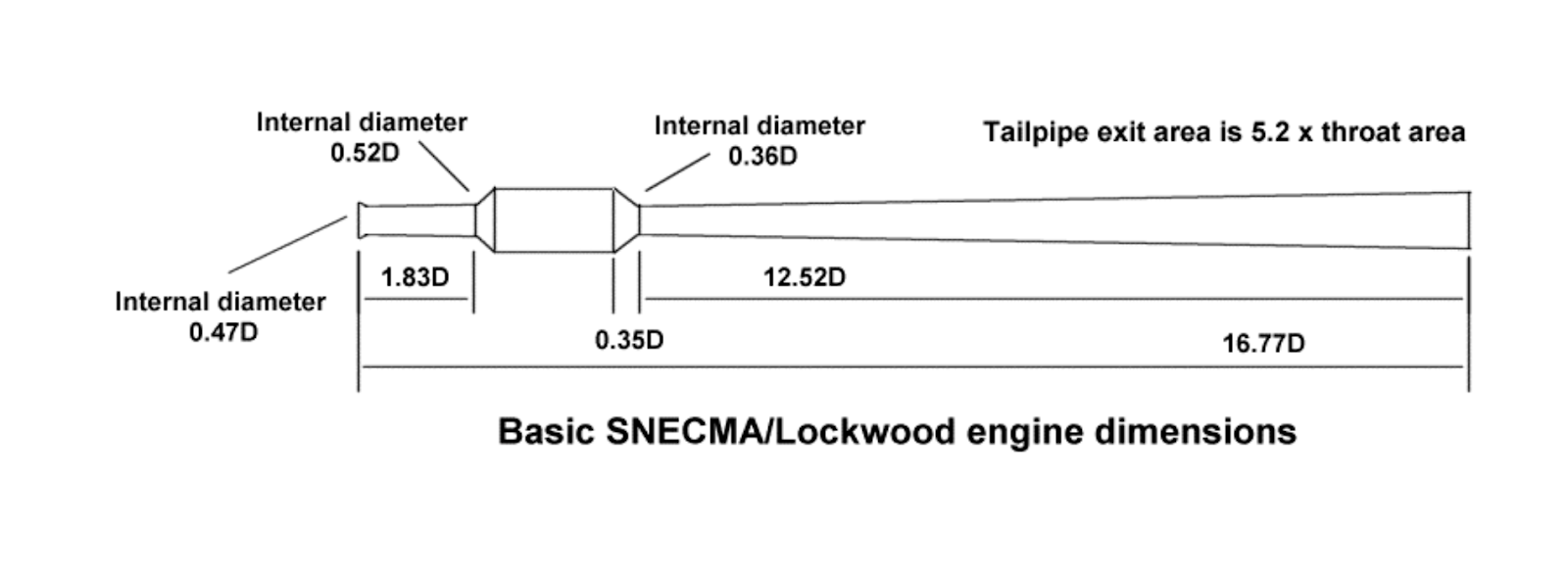

The goal was to build a pulse jet engine following the SNECMA/Lockwood design. Pulse jets are known for their simplicity, having no moving parts, yet producing thrust through rapid combustion cycles.

Construction Blueprint

Using the reference dimensions provided, the engine was assembled from steel pipes. The design featured a series of progressively narrowing and expanding sections to achieve the necessary airflow dynamics. The challenge was in connecting the pipes and maintaining the precise ratios specified in the blueprint.

Using the reference dimensions provided, the engine was assembled from steel pipes. The design featured a series of progressively narrowing and expanding sections to achieve the necessary airflow dynamics. The challenge was in connecting the pipes and maintaining the precise ratios specified in the blueprint.

Fuel and Ignition: Propane vs MAPP Gas

Initial tests used propane as the fuel source. However, the burn rate wasn’t fast enough to sustain continuous combustion. Switching to MAPP gas yielded better results, though ignition remained inconsistent.

Airflow Management

Given the difficulty in achieving stable operation, an air compressor was rented to provide a steady stream of fresh air. This external airflow injection proved essential, allowing the engine to run briefly. Although it only worked momentarily, the engine produced the characteristic pulsing sound and thrust, showcasing the core principles of pulse jet operation.

Results

Despite the limited run time, this project was a successful proof of concept for a one-day build. The experience highlighted both the simplicity and challenges of working with pulse jet designs.